by Purba | Jul 9, 2022 | Shout out |

Fashionnovation is on its mission to introduce you with the sustainable fashion brands and the tools to enhance your brand performance. As a continuation, we have interviewed Marcel Mihálik, the Owner and Founder of M&L Creative-a digital creative agency that promotes sustainable brands using TikTok to maximize those brands’ sales. During Marcel Mihálik and his agency’s illustrious journey in the digital marketing world, he has figured out TikTok to be one of the most effective platforms to make a buzz and the agency is proving it again and again with its performance. To know more, Kazi Purba has made an effort to learn from Marcel Mihálik himself!

Mr. Marcel, we see that you promote sustainable brands on TikTok. What’s the story behind your endeavour and what motivated you to establish that? Would you please explain how your agency works?

Marcel Mihálik: I’ve started as a usual agency – we provided and offered Facebook as a paid service and we were helping brands that were sustainable or ethical break through on the market and get their products sold online. The motivation was simple, I had my own store where I was selling different products before. During that time, I fell in love with the advertising and the whole marketing strategy aspect of running a business.

To be honest I wasn’t really successful with the store and that’s when the idea of starting my own marketing agency crossed my mind and I also wanted to combine it with my passion for sustainability and help the brands that are already making a difference, make an even bigger difference with online marketing.

Marcel Mihálik, the Founder and Owner of M&L Creative. Courtesy: M&L Creative.

The way our agency works, you could say, we try to provide a hands-off experience for our clients where we handle their marketing campaigns and even creative production to the point where we can run and successfully sell services and products of our clients, without them even being necessarily involved in the process. We start with onboarding to understand the brand’s situation, market and goals and we translate that into the strategy. We implement and completely outsource and keep our clients well updated on the progress while making money for them on automate.

What’s your offering?

Marcel Mihálik: Our offer changed over the time as we experienced iOS 14 and iOS 15 updates being introduced from Apple which made advertising on Facebook much more difficult. We couldn’t track the data properly and make the decisions anymore, so we needed to find some quick solutions. We were able to get tracking back on point to 90-95% but with Facebook’s constant changes it stopped making sense for smaller businesses, which were our primary clients. Nowadays, there are even issues with Facebook accounts getting banned for no reasons at all – it made sense for us to transition into Tik Tok, not for the platform itself, but for the possibilities that it offers.

So right now we’re doing the complete solution on Tik Tok. We handle organic growth, building the social proof, creating user generated content with our pool of influencers from all over the world and our in-house creative studio, altogether making as much ROI for our clients as possible.

Why choosing TikTok? What special do you offer to your customers?

Marcel Mihálik: You can compare TikTok these days to Facebook in 2015. It’s not a platform where you just find children dancing anymore as you may think, it formed into a platform where you can find people that are above 60 years old, you can find people that are watching science and tech stuff, cooking recipes all the way up to different building materials to use and different contents that you would find only on TV or on YouTube. It became a platform where people that are tired of YouTube and Facebook come to discover new topics and get a higher dose of dopamine in the form of quick edits and fast paced videos which are designed to keep a person hooked on the platform for as long as possible.

With all of these aspects people are drawn to TikTok and are spending their time there more than on other platforms. Right now, it’s the ideal place to promote your product. The biggest key to being successful on TikTok though, is that you mustn’t sell anything in the obvious ways like you did on other platforms and that the 80 to 90% of success is the actual video that you posted. With UGC’s being so vital, that’s what we’re mainly focusing on to make our campaigns successful.

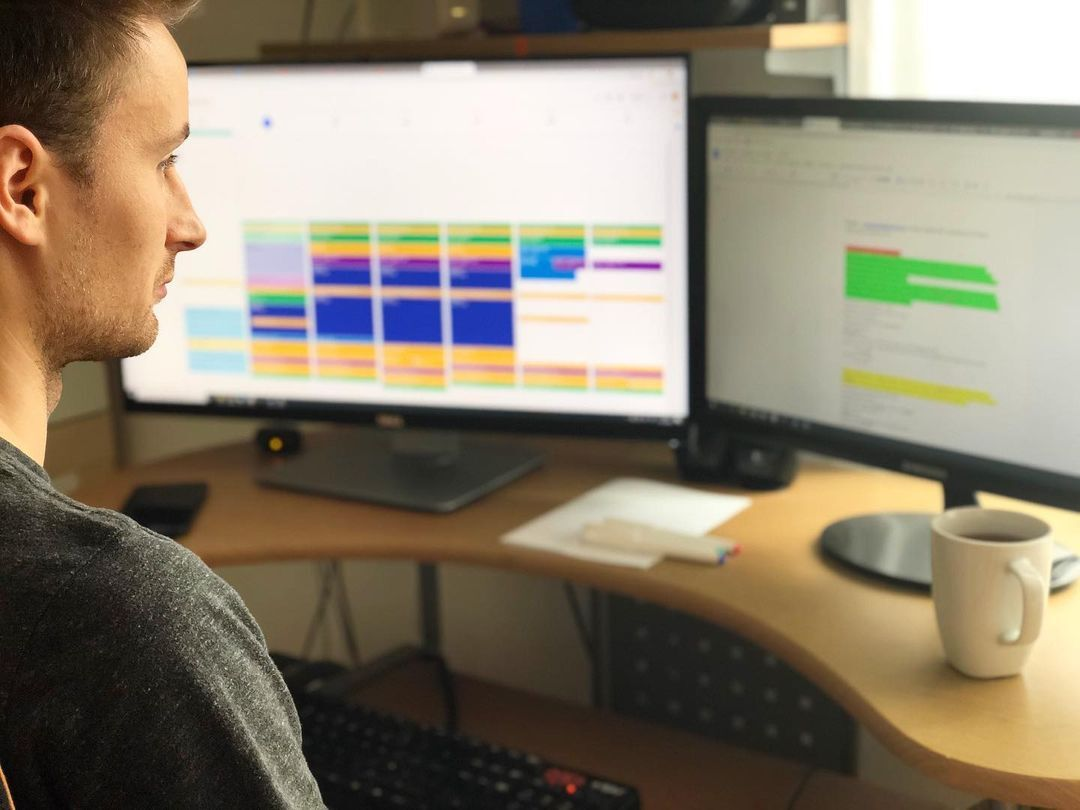

Figure: Mr. Marcel, working on a project. Courtesy: M&L Creative.

Does M&L Creative care about environment and sustainability? How are you promoting sustainability with your works?

Marcel Mihálik: As an agency we’re trying to be an example when it comes to being sustainable and ethical. One of the ways we’re doing it in our agency is that we have team members all over the world without strict working hours and without a physical office, that allows us to work efficiently, while also sparing the environment of the emissions from our travels to work and back home everyday. We also make sure that our team is able to work whenever it suits them and be compensated accordingly with emphasis on a performance fee which is multiple times higher than just the base salary, so the potential that we are offering is limitless.

For us, the best promotion for sustainability is working only with clients that are 100% ethical and sustainable brands. It’s not necessarily the claims we have, but actually making a difference brand by brand, customer by customer, until we eventually change 1% of the world, that will influence more people than we can ever reach. We believe actions speak louder than words and to showcase what we actually believe in, there’s no better way.

Cherry on top is that if we advertise these brands on TikTok and highlight those sustainable and ethical benefits, since GEN Z is still the prevailing generation on TikTok, it’s really easy to sell there and that gives us an advantage over our competitors.

What are your future plans with your agency?

Marcel Mihálik: Our plans are to become the number one choice for sustainable and ethical brands that are looking to make an impact in the world and hit the market in the right spot. On top of that, we’re planning to launch multiple initiatives that will be funded by us to help people and the environment in need with different issues at hand. We believe that the future of any business is to be a brand that is putting the well-being of others before their paychecks, and we want to be leading this ideology for other businesses to follow.

Find them through the following website: https://mlcreative-agency.com/

You can also read our other shout-outs which covers the story of Mari Michel: A Brand That Rescues Silk From Second Hand Men’s Ties and Turns Them Into Unique Accessories.

You can read all of our shout-out contents here!

by Purba | Jun 25, 2022 | Top Trends |

What is a Bimbo? Bimbo Definition?

(more…)

by Purba | Jun 17, 2022 | Academic |

Color forecasting in fashion possesses a great importance because color is an integral part of fashion and fashion design as a marketing tool. Color forecasting takes into account the color evolution, social and economic trends, consumer preferences and other influences. Colors are forecasted by synthesizing color direction from signs, hints and traces in the cultural environment. Let’s dive into the realm of color forecasting in fashion in details!

Objectives

- Appreciate color as a marketing tool

- Understand the process of forecasting color, taking into account color evolution, social and economic trends, consumer preferences and other influences.

- Recognize color forecasting as a coordinating factor in the apparel supply chain from fiber producer to retailer.

- Become aware of the techniques forecasters use to synthesize color direction from signs, hints and traces in the cultural environment.

Color Forecasting

- One of the most important function of the design director is to forecast color. Company’s fashion forecasters attend the trade shows in United States and Europe and participate in the professional color forecasting services.

- Color forecasting begins with attending the brain storming meeting with other forecasters at an international meeting of color professionals.

- Each participant creates a concept board proposing a direction for colors that will dominate fashion two years in the future.

- Color decisions begin early in the product development cycle. For designer a new collection begins with the selection of a color palette. From the first step it will be from six months to nearly one year before those colors appear as a coordinated collection on the runway or in the showroom.

- The color story combines into prints, yarn dyed fabrics, and solids and coordinated across jackets, tops, skirts, pants and dresses into a collection .

- Professional color organizations bring together experts to collaborate on forecasts for industries such as women’s wear, men’s wear, children’s wear and residential and nonresidential interiors.

- Forecasting for the American consumer began in 1915 with the founding of the Textile Color Card Association of America, predecessor to today’s Color Association of the United States (CAUS).

- Group of manufacturers and retailers used textile industry specialists to select fashion shades that would be popular in the future.

- The idea of forecasting trends in the marketplace boomed in the years after World War II. Trend merchandising entered the mass market in the early 1980s when trends became a coordinating factor for full product lines that extended beyond a single merchandise category.

- Today, trend merchandising and color forecasting are an integral part of product development.

- Color forecasters work 18 to 24 months in advance of the season to provide input for the designer’s decisions. To work so far ahead, Color forecasters/experts must combine knowledge of color theories and human behavior with acute observational skills.

- The experts spot new color directions at a trade show, on the fashion runway or in the streets.

Color Forecasters

Color forecasters forecast the colors by synthesizing the mood of the times from all the diverse elements of the culture – the economic conditions; happening in the fine arts; and music, movies and TV shows that top the charts – color forecasters track the trends and recognize new directions.

- Color looks different depending on the fabric, so color forecasters also stay up to-date on new developments in fibers, yarns and fabrications.

- To accomplish the task forecasters needs a background in the industry, a network of contacts and requires to travel the globe attending relevant trade shows and shopping the locales where new ideas originate.

Color in Marketing

- Marketing fashion means positioning the product in the marketplace. Color plays a major part in positioning apparel products by attracting attention, establishing the image of the product and the brand and evoking symbolic associations.

- Marketers use the psychological power of colors to communicate with consumers through advertising, brand logos, packaging and product colors. A consumers first impression of a new product is largely mediated by the color.

- Some fashion companies have signature color ranges – Calvin Klein’s use neutrals and Tommy Hilfiger’s bold primary colors, but others follow seasonal color trends.

- Emotions associated with hues and desire for individuality and personal expression through color selection influences the selling of different color products.

Color tends to identify the target market, for example – bold primaries for children’s products and trendy whimsical colors to appeal to teens. With influences from television, toy marketing and computers, children’s preferences tend towards bright colors that adults generally avoid.

Color Segmentation

Segmentation by color preferences makes it important for product developers and marketers to carefully observe the target market – watch consumers in their natural habit, read what they read, listen to their music, watch their movies and research their preferences.

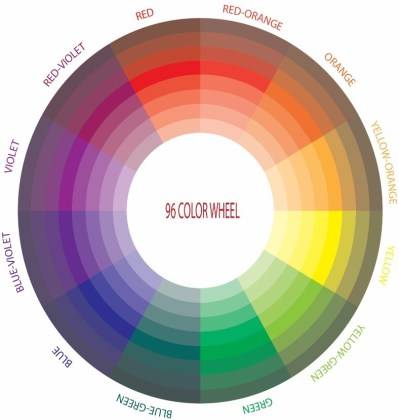

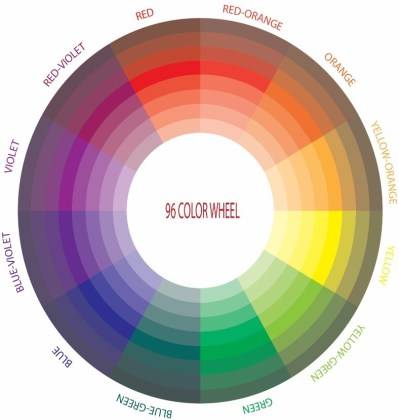

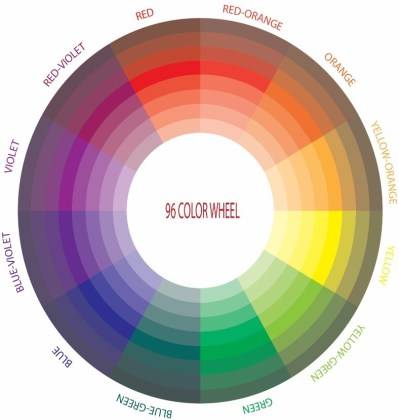

96 Color wheel. Photo courtesy: Tanvir Ahamed Fahad.

Psychology of Color

- The power of color comes from its symbolic meaning for people. Colors can represent experiences, emotions, status and other types of information that are difficult to conveying written or spoken language.

- Some color symbols have religious origin: such as Mother Mary in Blue as a symbol of Truth and Justice. According to some mythology Green is the symbol of Fertility.

Influencing Factors in Color Forecasting

Different factors influences the psychology of color preferences. A study showing a consistent order of color preferences in adults: the first choice was Blue, followed by Red, Green, Purple, Yellow and Orange.

Culture

- Cultural influence: Same color is interpreted differently in different cultures. A research found that most primitive cultures distinguish meanings mainly between Black and White. If a third color is used it is always Red; the next two colors are Yellow and Green; then Blue is added.

- Blue as protective color toward off evil spirit can be found in cultures as disparate as the middle east and Native Americans in the Southwest.

Culture & Status in Color Forecasting

- Due to increasing global communication and trade, the color forecasters must constantly investigate the cultural symbolism and cross cultural implication of color.

- Color preferences associated with Cultural Status – lower socio economic consumers tend to prefer simple colors and higher income people prefers more complex and newer colors.

Environment in color forecasting

Regional and Environmental Conditions: also play a major role in color preferences. Polly Hope an artist has observed – color as a representation of a country’ personality. She finds a distinctive “color conception of a place” that results from the combination of the natural environment and the indigenous culture.

Ethnic Identity/ Geographic Region

- Ethnic Identity or Geographic region has a relationship between color preferences. A survey in USA found White consumers were more likely to select Red, AfricanAmericans prefers Black and Hispanics Bright Blue.

- Color preferences can arise from personal experiences – for example, a person’s positive or negative reaction to the color develops as their parents chose for them in childhood.

- American consumers selects mid-range blue is consistently selected as the favorite color.

Issues

Green became important in all categories of products from Tshirts to automobiles to kitchen appliances when consumers became acutely aware of environmental issues in the early 1990’s

So there is a collective color preference underlying the surface of seasonal fashion change.

Different Meanings

In today’s complex color landscape a single color can have multiple symbolic meanings. In 1995 a survey signified the color Black as mystery, power, masculine, depressing and conservative.

Consumer Categories according to Color Preferences

- The Cooper Marketing Group divides consumer into three categories: color forwards, color prudent and color loyal.

- The color forward consumer enjoys being the first to try a new color but may shop for color ideas at both discounters and upscale department stores.

Consumer Categories

- The color prudent are the main stream consumer and wait until a color has more wide spread acceptance before buying it.

- The color loyal play it safe with color, sticking with classic blue or grey instead of choosing fashion colors.

Judgment of such mental images can help color forecasters justify their color choices and clarify the fit between color selection, product category and the consumer target.

General terms are not sufficient for communicating color information for design and manufacturing. Exact identification, matching and reproduction of colors requires an effective system with colors arranged in sequential order and identified with numbers and letters. Such systems are based on basic three characteristics of colors – hue, saturation and value.

- Hue: refers to the color – each color system designates a set of basic colors.

- Saturation (also called intensity or chroma) refers to the strength or purity of color.

- Value: lightness or darkness of color

- Tint: the term Tint applies to any color when white is added

- Shade: refers to colors mixed with black Tone: describes a grayed color.

Color Wheel

Seasonal Color Analysis

- In this system color grouping relates to natures four seasons – spring and autumn have a warm undertone, summer and winter have a cool undertone.

- The seasons are further defined by the saturation of the colors

– spring and winter colors are clear, bright and vivid;

- – autumn and summer are more subdued and less intense.

- The goal was to provide consumers with insight into the “right” colors to enhance their personal coloring and the “wrong” colors that should be avoided.

Colors for Four Seasons

|

COOL |

WARM |

| BRIGHT |

Winter

•Cool Undertone

•Colors Clear & Bright |

Spring

•Warm Undertone

•Colors Clear & Bright |

| LESS INTENSE |

Summer

•Cool Undertone

•Colors Subdued |

Autumn

•Warm Undertone

•Colors Subdued |

Color Names

- Changing the color of a product keeps the appeal of the new when the product itself does not change much.

- The color forecaster works in the two worlds of color naming – writing product specifications using the notation of particular color systems and marketing using color names that coordinate with a theme.

- Naming a color for marketing means drawing attention to its attributes by linking the color with the consumer’s perceptions.

- For example, a light brown “café au lait”- no two people would visualize in the same way. But the theme (a delicious and deluxe cup of coffee), the season (autumn), the color key (warm), the color family (brown) and the value of the color (light) all are conveyed by the color name.

- Even fashion ability can be captured in the color name if it recalls cultural references. In case of “café au lait” the reference is to coffee bars and gourmet coffee as high fashion concepts.

- Naming colors takes imagination, sensitivity to fashion change across product categories, an understanding of the consumer’s perception of colors and the insight to make connections between color and the product’s end use.

- Most color names come from associations in the environment.

- Natural phenomena: sky blue, sunshine, grass green, snow white

- Flora: Poppy red, moss green, mahogany, orchid.

- Fauna: flamingo pink, robin’s egg blue, dove gray.

- Gemstones, minerals, and metals: amethyst, lapis, amber, slate grey, copper.

- Food & Drink: caramel, apricot, champagne, burgundy.

- Spices: cinnamon, paprika, curry.

- Dyes: indigo, cochineal

- Building Materials: brick, terra-cotta, bronze.

- Location: Capri blue, Pompeian red.

- Today the color forecaster, the manufacturer, and the retailer routinely use color names to link fashion change to shifts in the culture.

This resource is taken from the lecture material of Mozahida Akhtar, Lecturer, Department of Textile Fashion and Design, Bangladesh University of Textiles (BUTEX).

Related articles:

Color Psychology: Which Color Means What?

To know the biggest fashion trends of 21st century, you can visit here! Moreover, if you want to know the future of fashion industry after Covid-19, you can click here!

And if you want to read one of our premium case studies on Fast Fashion Vs Slow Fashion, you can go here!

More related articles:

Color psychology: which color means what?

by Purba | Jun 16, 2022 | Academic |

Fashion Brand Development

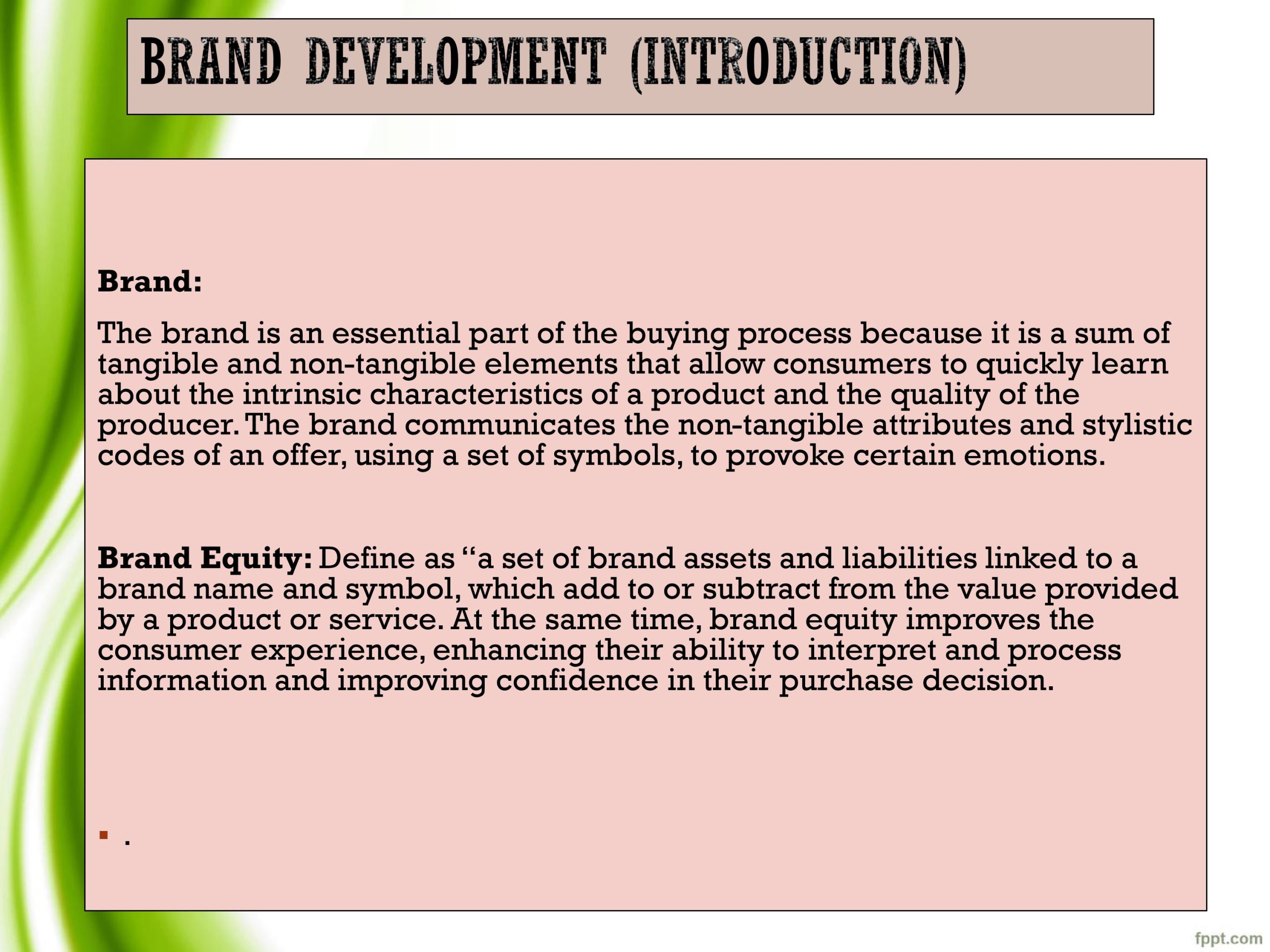

In this article we will learn various aspects of fashion brand development which includes the four choices to develop a brand, important definitions, classification of brands depending on target segments or the positioning strategy, brand strategy, brand development principles, branding process, etc.

Introduction of Fashion Brand Development

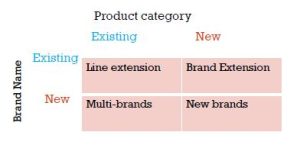

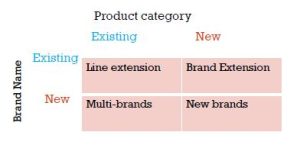

A company has four choices when it comes to developing brand. It can introduce line extension, brand extension, multibrands or new brands.

4 choices of developing a brand.

- Line Extension: Line extension occur when company extends existing brand names to new form, colors, sizes, ingredient or flavors of an existing category.

- Ex: Bata one of the oldest footwear brand in most countries, has expanded its footwear line to includes regular shoes, premium shoes, sports shoes, sandals.

- Brand extension: A brand extension extends a current brand name to new or modified products in a new category.

- Ex: Nestle has leverages the strength of its Maggi brand to launch several new lines; Maggi Noodles, Maggi Soup, Maggi Tomato Katchup.

- Multi-Brands: Companies often introduce additional brands in the same category. Unilever and Procter & Gamble markets many different brands in each of their product category.

- Ex: Same category such as shampoo, Bangladeshi Unilever introduce multi brands such as Sunsilk shampoo, Dove shampoo, Tresmme Shampoo.

- New Brands: A company might believe that the power of its existing brand name is waning and a new brand name is needed. Or it may create a new brand name when it enters a new product category for which none of the company’s current brand names are appropriate.

- Ex: Tata motors created the separate ace brand, targeted toward small transporters or those who have just started their transport business.

- Branding is personalizing a product to ensure a balance between different economic values. The aim of branding is to make a link between the character of an object and its branded image or form. Branding is a disciplined process used to build awareness, attract new customers and extend customer loyalty.

- Brand identity is tangible and appeals to the senses. How a business presents itself to — and wants to be perceived by — its consumers.You can see it, touch it, hold it, hear it, watch it move. Brand identity makes big ideas and meaning accessible.

- Brand Image- The way a company chooses its name; designs its logo; uses colors, shapes and other visual elements in its products and promotions; crafts the language in its advertisements; and trains employees to interact with customers – all with the goal of cultivating a certain image in consumers’ minds.Brand image is the actual result of these efforts, successful or unsuccessful.

- Brand Governance: Brand management requires strategy, planning and orchestration. It begins with thoughtful leadership, a shared understanding of core purpose and brand fundamentals and an imperative to grow brand equity. It’s finding new way to delight customers, to engage employees, and to demonstrate your competitive advantage.

- Brand Architecture: The term “brand architecture” describes the organization and structure of the brand portfolio, specifying brand roles and the relationship between brands and between different product-market contexts. Well-developed and managed brand architecture generates clarity, synergy, and brand leverage—three goals of brand architecture.

Brand Name

A brand is a name. Something that you can speak. Sometimes, it’s a symbol. Sometimes, it’s a design. Brands are important to the consumer because it enables the marketer to create perceptions and images that the brand presents. If we can get the consumer to perceive that one brand– or our brand– is better than our, our competitor’s brand, that perception becomes their truth. That truth becomes a purchase. The part of the brand that can be spoken is called the ‘brand name.’

What’s a Brand Mark?

The key to a brand is to have it legally trademarked through the Trademark Office so that you can be sure that no competitor can have use of the name or the symbol. If you look at the Nike, you automatically know that it is Nike. That is called the ‘brand mark.’

The classification of fashion brands

Depending on target segments or the positioning strategy, brands can be classified into four categories: 1.Griffe, 2.Luxury brands, 3.Premium brands, and 4.Mass-market brands. The higher the price range, the narrower the target audience as fewer people can afford it.

- 1.Griffe, or designer brand: Is at the top of the pyramid. The term griffe is derived from handwriting and refers to the pure creation of an item by hand, created in atelier. Thus, it is unique, irreproducible, and eternal. Yves Saint Laurent is an example of griffe.

- 2.Luxury brands: Luxury brand, which originates from either designer brands (e.g., Dior and Chanel) or craftsmanship (e.g., Gucci and Louis Vuitton). Luxury brand has six features: excellent quality, high price, scarcity and uniqueness, aesthetics and polysensuality, ancestral heritage and personal history, and superfluousness. The essential elements of luxury products are craft, uniqueness, exclusivity, and artistic talent—though some crafts have been replaced by machines.

- Luxury brands offer excellent quality, scarcity and uniqueness, and excellent aesthetics and poly-sensuality— all of which claim these products a high price. Luxury brands are also characterized by its ancestral heritage, personal and cultural history, and geographical roots. The last characteristic of luxury brand is its superfluousness. Luxury brands are often described as those “brands that no one really needs, but everyone desires. Originally, luxury items were made for royalty, aristocracy, and the upper class until the nineteenth century. As such, luxury brands have a strong connotation of success, allowing consumers to attain a privileged social standing through these items. In the luxury fashion area, the ‘brand name’ is everything, because it is the name and the logo that attracts the consumers and creates an often long lasting relationship between them and their selected ‘luxury brand’. It is the first contact between the brand and the consumer and should reflect everything the brand stands for.

- Keller (2009) defines ten characteristics of ‘traditional-luxury brands’, offering strategic brand management applications. (1) A premium image for luxury brands is crucial and therefore the control of this image as well. (2) Luxury branding involves the creation of many intangible brand associations and an aspirational image. (3) The marketing program must ensure that the quality of the product and service is aligned to guarantee an extraordinary experience for the customer. (4) Brand elements, such as the brand names, logos, symbols, packaging, signage etc., can be important drivers for ‘brand equity’. (5) Drives for ‘brand equity’ in luxury could be associations from linked personalities, events, countries or other entities.

- (6) Distribution must be strictly controlled through selective distribution channels. (7) ‘Luxury brands’ should follow a premium pricing strategy. (8) ‘Brand architecture’, which is the amount and nature of common or distinctive brand elements that are applied to products sold by the company, must be managed carefully. (9) Competition for luxury brands must be defined broadly, as those brands often compete with other luxury brands from different categories. (10) ‘Luxury brands’ must protect their trademarks legally and strictly to fight counterfeit goods.

- 3. The third brand category is premium brand: Also called new luxury or new luxe, premium brands have elements from both luxury and mass-market brands. They are at the top of the mass-market spectrum concerning price, yet at the same time they are more accessible than luxury brands. Premium brands have refined their products and branding strategies, proposing alternatives to luxury for a better value. Truong et al. (2009) give some suggestions how ‘new-luxury brands’ could be managed and suggest that brand managers should invest resources to create a prestigious environment around the brand, so it appeals to the consumers as something they need to aspire for. They can do this by establishing visually attractive and prestigious stores or divisions in department stores and through advertisements in glamorous magazines, holding fashion shows and signing up well-known designers. Limited price premiums (temporary discounts) shall ensure that the middle class consumer has only occasional access to the brand.

- Premium brands have three sub-categories:

- Super-premiums: Priced at or near the top of their category such as Emporio Armani, these brands target consumers who belong to classes immediately below the traditional pure luxury customers.

- Old luxury brand extensions: lower-price versions of products created by companies such as Valentino Prêt-à-Porter whose brands have traditionally been affordable only by the rich.

- Masstige: Priced well below super-premium or old luxury brand extensions such as Victoria Secret. It is oftentimes premium in terms of price and quality among mass products.

- The critical success factor of the premium brand strategies lies in the prestige, differentiation, and a reasonable premium price. Companies need to invest resources to create a prestigious environment around the brand in order to promote public aspiration for the brand. Such an environment is created through availability in prestigious stores or sections in department stores, advertisement in glamorous magazines and fashion shows, and involvement of well-known designers. At the same time, adequate price premiums ensure limited access to the brand for the mass market. Ideally, middle-class consumers should have only occasional access to the brand.

- 4. The last brand category is mass-market brands/non-luxury brands/Classic: Products in these brands are generally mass produced, widely distributed, and have a low selling price. The quality level of these products are acceptable. The mass-market brand caters for a wide range of customers, producing ready-to wear garments using trends set by famous names in fashion. In order to save money and time, they use cheaper fabrics and simpler techniques that can easily be produced by machines. Examples of mass-market brands are those found in mass retailers such as Tesco, Wal-Mart, Marks & Spencer, or specialty stores such as Old Navy.

- Fashion brands can also be categorized by their distribution strategy as national or private label brands. Also called retail brands, private labels, and store brands, these are brands of retailers—not producers and designers—who commission the production, market the products under their store name, and own the right to sell the brand exclusively in their retail outlets.

- Examples include Club Room, INC, and Alfani, the private brands of American Macy’s department store. Chain retailers such as Gap, Ann Taylor, H&M, Top Shop, Next mainly sell their private brands only in their stores, and oftentimes, their brand and store names are the same. The target of private brands ranges from mass market to premium brand, and retailers are increasingly developing more private labels for differentiation. In contrast, manufacturer brands are carried out by producers who have direct control over them. These brands are distributed in the national store chains, the reason they are also called national brands. Examples include Mexx, Guess, and Ralph Lauren.

WHAT’S A BRAND STRATEGY?

Brand strategy is a long-term plan for the development of a successful brand in order to achieve specific goals. A well-defined and executed brand strategy affects all aspects of a business and is directly connected to consumer needs, emotions, and competitive environments.

Phase 1: Research & Audit

- An in-depth research and audit process lays the groundwork for all future branding efforts. The purpose is to identify where your brand is today, so you have a clearer view of where it needs to be tomorrow.

- To gain a historical perspective and a better understanding of your brand equity, you should begin by analyzing all of your current marketing materials. These can include:

- Mission statement

- Vision

- Value proposition

- Organization chart

- Business plan

- Marketing plan

- Annual reports

- Existing market research

During this phase, it’s also important to analyze your competitors’ brands as well. Part of this discovery phase is about uncovering your strengths, weaknesses, and (most importantly) opportunities in the market.

Phase 2: Define Your Brand

- Brand values – typically 4-5 words or phrases that describe the things your brand stands for.

- Mission –a statement that dictates what your ultimate aim is as a business.

- Vision – A statement that communicates the long-term impact of your work. While the mission may evolve over time, the company’s vision is unchanging.

- Brand story – a written narrative that describes where you’ve come from and where you are going. It’s usually conversational, and is rooted in purpose to inspire an emotional connection.

Phase 3: Position Your Brand

In developing a brand, the most important decision is its positioning. It’s time to make your brand tangible. This task can be accomplished by asking four questions: what is the benefit and purpose of the brand? who is the target potential customer? what are the differentiators that support and can create such a benefit? and who is the competition? This positioning process shapes the product mix and identity of the brand. The following outlines the basic elements you’ll need to think about during this phase.

Brand name

A good brand name is easy to spell, easy to pronounce, intriguing, and reflective of your brand’s core values.

It’s an immensely important element of one. A well designed logo will reflect your brand’s personality.

The logo of Fashionnovation created by Kazi Purba

Typography

At this step, ask yourself: Do these fonts reflect my brand’s image? Are they aesthetically pleasing? Can my audience read them?

Color palette

Colors can trigger both direct associations (sky blue, green grass) and indirect associations (passion, creativity, authority), adding an important layer of depth to your brand’s identity. Choose wisely, and choose intentionally.

Phase 4: Brand Awareness

All of your research, positioning statements, visual assets, and messaging should be combined into one comprehensive brand book (commonly referred to as a Style Guide).

When done properly this book will ensure consistency, both internally and externally.

Phase 5: Brand Measurement

Building your brand takes significant time, research and resources. Once your brand is established, you can’t just let go and forget it. A brand needs to be monitored and measured on a consistent basis.

Measuring internal and external performance will include speaking with your staff, customers, and even monitoring conversation online via social listening tools. Ask your team if they understand the target audience, customer insights, and brand drivers. Ask your customers if they recognize your logo, know what your brand stands for and hold a sense of loyalty to your brand.

- Once a brand and its positioning is established, a firm needs to communicate the brand to its customers. As a firm grows, a brand alone may not be enough to address the customers’ diverse needs and increase market share. Two important decisions in brand growth should be focused: brand extension and brand portfolio strategy.

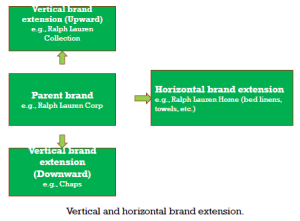

Brand extension: The use of an established brand name to introduce a new product or class is one of the most highly utilized growth strategies in the fashion industry. Given that new product development requires high cost and its success is not high, brand extension is an economical option for fashion companies to increase their market share by leveraging the value of their existing brands.

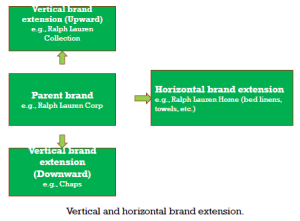

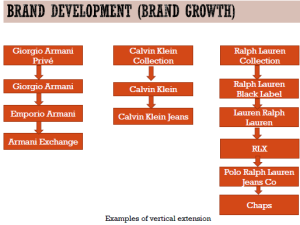

- The brand that gives birth to a brand extension is termed the “parent brand.” There are two types of brand extensions: horizontal (also called category extension) and vertical (or line extension). Brands extend horizontally to a new product class or category not currently offered by the brand but at the same price and quality level as the existing brand. Examples of horizontal brand extension include Prada’s introduction of fragrances and eyewear within the same price range and quality level as their parent brand. Brand can also extend vertically within the same product category either upward to target a more affluent market or downward toward more price conscious consumers.

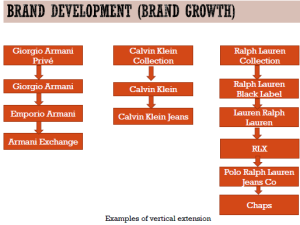

- In the fashion industry, vertical downward extensions are more common than vertical-upward with many high-end fashion brands offering products at lower prices to capitalize on the value of their prestigious brand name. Examples include Giorgio Armani’s Emporio Armani and Armani Exchange, Calvin Klein’s CK, and Donna Karen’s DKNY and DK.

- Ralph Lauren has sixteen levels of brands ranging from their highest level runway brand, Ralph Lauren Collection, to the brand at the lowest price point, Chaps, which targets the mass market and price-conscious consumers. Through brand extension, fashion firms reap numerous benefits—reducing the cost of developing a new brand including expense of introductory and follow-up marketing programs, increasing sales from additional consumer segments, and improving brand image and market coverage’s.

- However, the main issue with brand extension is the risk of diluting the parent brand image or confusing consumers.

Vertical and horizontal brand extension

Example of vertical extension

Brand portfolio strategy:

- Another way a company can grow is by creating new brands to meet the demands existing brands cannot satisfy. A company would thus carry multiple brands, or a “brand portfolio’’. A brand portfolio is defined as a set of brands owned by one company or all the brands and their extensions, offered by a given company in a given product category.

- The decision about how to organize and manage a set of the brands is called a “brand portfolio strategy” or “multi-brand strategy.”

- The main question in a brand portfolio strategy is the relationship and domains among brands within the company. Failure to coordinate new brands with others in the portfolio can result in an incoherent combination. As such, companies must have a long-term vision for every brand in which roles and relationships among brands should be carefully defined.

- Two main approaches exist in brand portfolio strategy:

branded house and house of brands. A prominent example of a branded house is Armani. Each sub-brand is marked with the name Armani: Emporio Armani, Armani Casa, Armani Jeans, Armani Junior, Armani Caffé, Armani Fiori, Armani Hotel

- . Hugo Boss serves as another example of branded house. Their brand portfolio includes five brands distinguished by colors. Boss in black logo offers the comprehensive spectrum of elegant business ensembles, casual sports clothing and evening wear. Boss Selection is another Boss brand in black color offering the premium tier. Orange color of Boss focuses on casual fashion while Green, on golf collection. The brand “Hugo” in red colored logo offers men’s and women’s with unconventional and avant-garde fashion.

- The branded house approach requires a minimum investment for each new brand because it leverages the status of an established name. This approach satisfies the three goals of brand architecture: clarity, synergy, and leverage. The advantages of this approach include effective increase of brand equity and enhanced marketing efficiency. A drawback to this approach is that if a brand within the portfolio falters, other brands suffer as well.

- The other approach, house of brands, contains independent and unconnected brands. Oftentimes the corporate name is not evident, and as a result, consumers are unaware of the company to which the brand belongs.

- A prominent example of house of brands is the VF Corporation, which owns and manages more than 30 brands. Major brands in their portfolio include North Face, Nautica, Lee, Wrangler, Timberland, Kipling, and Jansport. In this approach, association among brands can be avoided, thus establishing an independent brand image that focuses on specific markets. While this approach may be inefficient in marketing, it allows companies to avoid negative spillovers that may occur in the branded house approach.

Fashion branding is a process whereby designers, manufacturers, retailers, and all those responsible for selling fashion create product differentials, competitive advantages, and give the product itself a unique identity. Fashion branding is about creating a clear vision, a clear direction, a clear focus, and strategy for the company.

Branding Tells a Price Story

The image of a brand, however, in reality, is reflected in its price. Customers expect to pay a high price for exclusive brands, like Chanel, Dior, Balenciaga, Gucci, as price is an indication of status, self-esteem, and quality. On the other hand, popular-priced brands’ value and uniqueness match the perceptions of the customer’s self-image. Value for the product and uniqueness of the product and the brand give you a self-image.

From that point of view, we have to deal with inexpensive brands. Now what are they? Inexpensive brands reflect dollar value. That’s the key issue. Dollar value. In terms of self-accomplishment and value, topping the list due to perceived expertise and reasonable cost. So, what do we look at there? Wal-Mart, Target, Home Depot.

Branding Tells a Story

Branding really deals with telling a story. We all like to be thought of as storytellers, and that is exactly what we are. We’re telling a story in order to make an emotional connection to the consumer. The consumer needs an emotional connection and a passion for the brand, for the symbol, for the product. In actuality, the brand must reflect the image of the product and become a personality. The reason for that is because the customer identifies with that brand and takes on that personality of the brand. They become the brand. Once you identify with the brand and you are wearing the clothes or using the product in any way, you become that brand and that product. US and German fashion brands tell beautiful and effective stories to their customers. Actually all favourite fashion brands convey a story.

This resource is taken from the lecture material of Mozahida Akhtar, Lecturer, Department of Textile Fashion and Design, Bangladesh University of Textiles (BUTEX).

Book: Fashion Branding and Communication by Byoungho Jin and Elena Cedrola.

To know the biggest fashion trends of 21st century, you can visit here! Moreover, if you want to know the future of fashion industry after Covid-19, you can click here!

And if you want to read one of our premium case studies on Fast Fashion Vs Slow Fashion, you can go here!

Content marketing is extremely important for brand development, to know more from our exclusive article, you can click here!

If you want to know about digital marketing strategies for fashion e-commerce, you can go here!

by Purba | May 27, 2022 | Academic |

The famous fashion shows are based on the upcoming trends. Likewise Spring Summer 2022 Fashion Trends or SS 22 Fashion Trends can be traced from following the fashion shows. Luckily, the fashion shows are captured and broadcasted in YouTube which we can analyze. Here we are analyzing five fashion brands and their fashion shows along with their YouTube video links. Let’s dive into the part of the fashion trends of 2022!

Balenciaga Spring-Summer 2022

Balenciaga Spring-Summer 2022

Balenciaga Spring Summer 2022 Full Womenswear digital Runway Fashion Show collection by Demna Gvasalia

It is undeniably enlivened by the grid, which has a palpable impact. It’s chock-full of significance: private enterprise, class, destitution, the Soviet system, the monetary situation, the oppressed world’s innovative spirit, mainstream society, observation… People are claiming that Gvesalia is charging people thousands of dollars for “appalling” clothing worn by needy people, and they are completely true. You could argue that this makes him an extortionist, but I think it’s kind of brilliant, pushing the style that ordinary people who don’t care about design wear to its limit and then chucking it back in front of you like this. It makes you realize that what was in waiting for you was all around you the entire time; it’s like an outlandish depiction of how the vastness of the universe works.Isabel Marant Spring-Summer 2022 Show.

Video link: https://www.youtube.com/watch?v=HYnyIEJpnwo

Chanel | Spring Summer 2022 | Full Show

Chanel _ Spring Summer 2022 _ Full Show

Chanel | Spring Summer 2022 by Virginie Viard | Full Fashion Show in High Definition. (Widescreen – Exclusive Video/1080p – PFW/Paris Fashion Week) #Chanel #PFW #SS22

For a change, it’s wonderful to see PRETTY models on the runway, and as a result, this Chanel show is certainly one of the greatest of the season. The outfits, as well as the models, are stunning.

What a lovely assortment! Enchanting theme and feeling. In response to the comments regarding the models’ clumsiness, I received the distinct impression that they were coached to compete for the photographers’ attention (current cultural structures.) The beginning of the presentation is reminiscent of Victoria’s Secret. And if you pay attention to the music and the fact that the models’ egos were repeatedly ‘crushed’ by the next ‘lady up…’ The models grow more ‘dressed’ and’status professional’ as the presentation proceeds. By and by, with that astonishing silk assortment, the ladies had developed into a strong, reserved, certain, powers of nature. I say BRAVO!

Video link: https://www.youtube.com/watch?v=BLxM7yxo6Yk

The Dior Spring-Summer 2022 Show

The Dior Spring-Summer 2022 Show

Take your virtual front-row seat to discover the Dior Spring-Summer 2022 show by Maria Grazia Chiuri, being unveiled live from Paris. The prints were astounding!

I think the outfits were prepared for Jisoo to wear for her impending show. Albeit the outfits were basic and normal, the creation and idea were eminent! It shouts inventiveness out of Dior’s design style.

Video link: https://www.youtube.com/watch?v=fuwTQ2BCNOo

Versace Spring Summer 2022 | Fashion Show

The #VersaceSS22 collection is built from Versace’s iconic silk foulard.

“The foulard is an important part of Versace’s history and personality. It’s been used as a canvas for our signature prints and can be worn in a variety of ways, from knotted tops to headscarves to bag accessories, bringing Versace flare to any ensemble. The foulard has been a part of the brand since the beginning, but this season it’s flipped on its head: instead of being fluid and dreamy, the scarf is provocative, seductive, and tightly knotted.” Donatella Versace is an Italian fashion designer.

The scarf’s adaptability means it can be transformed into anything from billowing blouses to sultry, shrunken-fit gowns. The designs, when combined with iconographical prints, appear haphazard, unfinished, and unpolished. It’s as though the components have been pulled apart and then quickly reassembled.

The brand’s signature Safety Pins are used to hastily fasten slashes in the clothes. The Safety Pins have been updated in a variety of bright hues to serve as both a functional fastener and a dramatic adornment. Scarves encircle the torso and are punctuated by hardware that appears to be put at random. Sleek latex dresses, tops, and skirts in a striking color provide a textural variation.

The Versace foulard is distinguished by ornate prints. There’s a celebration of brand code La Greca this season, as well as new designs. Banquet Aftermath features dishes and cutlery from the Versace Home collection – the cutlery is also translated into knife and fork jewelry. Royal Rebellion features crowns and crests in bold colorways, and Banquet Aftermath features dishes and cutlery from the Versace Home collection – the cutlery is also translated into knife and fork jewelry. Versace’s take on spring blooms, Acid Bouquet, is unromantically unromantic in clashing acid tones.

Menswear is inspired by the foulard and features loose-fitting, printed silk garments. The silk shirt, which emerged from the patterned scarf, is a key component of Versace menswear. Form-fitting sportswear, skintight latex, and flirtatious handkerchief tops contrast with relaxed shirting and pajama ensembles. Yellow, orange, pink, and blue fluo tones are used to create sharp tailoring.

The La Medusa handbag line has been updated with new designs and colors, including a huge open tote and a drawstring-top bucket style, both with incorporated chain embellishments. The La Greca Signature Collection has also been updated with new hues. Scarves are draped from bags and fastened to handles, tying the accessories collection to the colorful foulard-inspired range.

Video link: https://www.youtube.com/watch?v=zsu2WRFaUoQ

GIVENCHY | Spring Summer 2022 RTW Show

Watch the Women’s and Men’s Spring Summer 2022 Collection show by Matthew M. Williams.

Creative Director: Matthew M. Williams

Music: Young Thug

Sound curator: Surkin

Set Design: Villa Eugenie

Styling: Panos Yiapanis

Casting: Piergiorgio Del Moro & Samuel Ellis Scheinman

Make Up: Lucia Pieroni

Hair: Duffy

Manucure: Anatole Rainey

Artist: © Josh SmithCourtesy of the artist and David Zwirner

Introduction Film by:

Director: Jasmine Loignon

DOP: Benoit Soler

Choreography: Kevin Bago

Model: Steinberg

This is fantastic. The use of black, white, and grey is always elegant. In a classic Gareth Pugh style, geometrical volumes are used for the women. I like how the long legging looks under the classic patterned shorts, creating a stylish, non-sporty look. The lila pieces and voiles were perfect for that. Luxuruous. Making androgyny look appealing. The color blocking with beige is fantastic.

Matthew M Williams is fast becoming one of the most influential designers of our time. His outfit, as well as his concept and execution, are amazing. I had chills the entire time I was watching this fantastic Fashion Show, a collection that perfectly suits the current Zeitgeist as well as the future.

Video link: https://www.youtube.com/watch?v=8JKrvQxkIE0&t=932s

To know the biggest fashion trends of 21st century, you can visit here! Moreover, if you want to know the future of fashion industry after Covid-19, you can click here!

And if you want to read one of our premium case studies on Fast Fashion Vs Slow Fashion, you can go here!

More related articles!

Bimbo Fashion

If you are interested to know the fashion nail trends of 2023, you can go here!

Fashion nails and spa: Trends and where to get one?