We can’t deny but calling a spade a spade that textile waste is a matter of great concern globally. Especially when it comes to the topic of fast fashion, then it cuts a sorry figure as it keeps a negative impact on the environment by consuming enormous amounts of water & energy. But we can bid fair if the recycling process & circular economy is introduced.

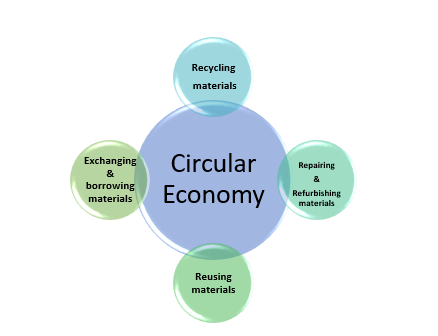

What is Circular Economy:

It’s a strategy of producing & consuming materials & components which introduces recycling process & reduction of waste. Minimizing maximum waste & pollution by ensuring maximum efficiency of resources is the main goal of the circular economy.

Figure : Strategy of Circular Economy

-

Textile Recycling:

A dynamic process which includes recovery of old clothing & other textiles for reusing or to recover materials is called textile recycling. It is a matter of glad that some companies are bringing upcycling practice into their habit.

-

Socio-Economic Advantage of Textile Recycling:

Textile recycling not only ensures environmental & ecological advantages but also it brings socio-economic impacts vastly.

- Product diversification can be introduced where some recycled fibres such as cotton, wool and cashmere, collected from both pre and post-consumer waste.

- Energy efficiency can be increased.

- This green procurement trend is appealing to the health sector too.

-

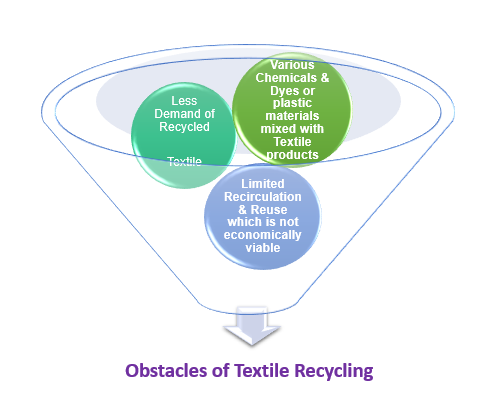

Struggles of Textile Recycling:

Very few countries are able to utilize 50% or more of their potential recyclable materials. Also the survey says, only 5% waste can be recycled in many regions. Some other struggles are:

- Fibre Blends Hinder Separation of recyclable materials:

The sorting process for recycling becomes difficult when fibers are blended.

-

Lack in Technological Knowledge:

Technologies are not that much updated so that textile wastes can be sorted accurately. Chemical & mechanical textile recycling technologies are also limited.

-

Structure of Textile Material:

Textile materials containing different types of chemicals & dyes often rein the process of recycling.

-

Lack of proper standardization:

There is no proper coordination & integration of increasing efficiency of the textile recycling ecosystem. Which is affecting the industry negatively.

-

Limited Public Participation & Awareness:

Knowledge barrier and attitude barrier of general people is a great obstacle in case of textile recycling. It is true that all the policies and standardizations will be trivariant if the public is not awarded!

-

Some Pros & Cons of Circular economy:

Pros:

- It is sustainable enough,

- Using of toxic chemicals is eliminated in circular economy,

- Less pollution can be ensured,

- Products’ life span is promoted,

- Economic Process.

Cons:

- 100% circular economy may not possible to achieve,

- All the products are not suitable to bring into circular economical process,

- Small industries may fail to introduce this process for not having technological knowledge.

Future of Circular economy:

Circular economy is the finest option through which take-make-waste i.e linear economy is mortified. It involves new design strategies which push consumers to use a product for a long time. It is basically the hero of a mighty environment which will save it from the cursed textile pollution by involving recycling & by reducing waste.

Nashita Ahmed

Department of Environmental Science and Engineering,

Bangladesh University of Textiles (BUTEX)

To read more articles of this author, you can visit the following links:

Cactus Leather Will Save 1 Billion Animals Killed for Fashion!

0 Comments