by Purba | Jan 9, 2022 | Shout out |

Fashionnovation is on a journey to introduce you with unique, sustainable, rising fashion brands, start ups and the masterminds behind them. As the continuation of our journey, Kazi Purba explored V’LE Magazine and the mind of its founder through some questions. In our today’s exclusive interview, we take the humble opportunity to introduce you with Bof Setlhare, a visionary founder of V’LE, a start-up based in New York, United States. Having a background in fashion working as a fashion model, keeping the idea of ‘fashion with purpose/fashion for good’, he is using his skills in fashion to manifest that idea to life. Today we will listen to his story of building up a network called V’LE to promote sustainable fashion around the world.

What is V’LE?

V’LE Magazine is a digital magazine focusing on sustainable and ethical fashion. We share academic insights related to sustainability (or lack thereof) in the fashion industry. We noticed that when people think of sustainability in fashion, there’s more emphasis on environmental and social aspects. So, the whole point of V’LE is to highlight other aspects that are not discussed in the mainstream conversations. We discuss political, economic, social, technological, environmental, and legal aspects. In a way, it’s a 360° approach because we recognize the interaction of fashion with all of these aspects. Another core element is our creative side. We do editorial shoots and relate them to the topic so that the articles aren’t too wordy. Lastly, we are a directory for sustainable fashion brands. On our Features page, we have sustainable brands with varying styles for consumers looking to buy more sustainably.

Why did you establish this platform? What was your drive?

I have a background in fashion working as a fashion model. During the covid lockdowns, many industries were going through sudden shifts and that got me thinking about this idea of ‘fashion with purpose/fashion for good.’

Bof Setlhare, the founder of V’LE as a fashion model. Courtesy: V’LE Magazine.

The next step was to figure out how I can use my skills in fashion to bring that idea to life. As a fan of academia, I realized the need for educational resources that promote awareness specifically when it comes to sustainable fashion.

Bof Setlhare posing for a photoshoot. Courtesy: V’LE Magazine.

Who are your audience?

The primary audience is fashion brands and consumers. The great thing is as niche as V’LE is, we cover a broad spectrum of subjects. People in tech, social services, psychology, environmental activism, federal agencies, etc., can find something they relate to. So basically, our audience is anyone interested in conscious fashion and longevity in fashion.

Please share some of your memorable incidents with V’LE.

I was happy when the website surpassed 100 visits lol. To be honest I can’t really single out any memorable incidents given our small size. I literally remember everything we’ve done. Being able to reflect on our operations and see how the process is different for every article, and just be grateful to have worked with amazing people. It’s a special feeling knowing that people (photographers, models, collaborators, and our audience) are giving us their time considering we’re a small startup.

Courtesy: V’LE Magazine

What is sustainability according to your view point? Can we really assure a sustainable future of fashion? How can V’LE support this grand endeavor?

There are 2 ways to look at sustainability; the brand side and the consumer side. The brand side focuses on the supply chain activities (from sourcing raw materials to point of sale) that prioritize sustainability and ethics. On the consumer side, it’s about information and resources that promote conscious consumption of fashion items. It’s also important to note that sustainable fashion isn’t a new thing and many cultures across the globe have been practicing it knowingly/unknowingly. It’s just that this conversation is becoming mainstream mainly due exponential growth of fast fashion and the urgency for climate change action. Sustainable fashion looks different for everyone depending on geography, culture, financial and economic constraints. The idea is to look at areas within one’s life and what role can they play to push the movement forward.

What are your future plans with V’LE?

In the future, we want to incorporate other elements such as e-comm with our own collection. Would also love to launch something in physical form rather than being exclusively digital. Creating a space rich in music, arts, culture, and fashion where people can come and interact.

Website link

V’LE Magazine

Social media links

IG- https://www.instagram.com

Facebook- https://www.facebook.com/VLE

LinkedIn- https://www.linkedin.com/company/vlemagazine

Tiktok- https://www.tiktok.com/@vlemag

Twitter- https://twitter.com/vlemag

by Purba | Nov 24, 2021 | Fashion events |

The FREE live event will take place on Friday the 26th of November at 3:00 p.m. CET / 9:00 a.m. EST. When you register for this event, you’ll get the chance to win an Amazon Card that can be used to buy a fashion design or business book to learn more and speed up your success! Link given in the end. The lockdown has made a lot of people think about where they are in their lives and about their careers. Some of them have even started to work for themselves. With the Fashion Café, Annette Lennerup from Fashion Design Tribe is going to help new fashion entrepreneurs by answering as many of their questions as possible. The Fashion Café is a live Q&A event hosted by Annette Lennerup from Fashion Design Tribe, where they’ll be answering questions about designing, manufacturing and starting your own brand. It’s a virtual event, so you can do it from your own home with the comfort of a nice cup of coffee. It will take place on Friday the 26th of November at 3:00 p.m. CET / 9:00 a.m. EST. During the event they’ll be answering questions like ‘How do I earn money to start my own fashion brand?’, ‘What tools should I use when I’m designing my collection?’ and ‘How do I negotiate my minimums with a manufacturer?’ When you register for this event, you’ll get the chance to win an Amazon Card that can be used to buy a fashion design or business book to learn more and speed up your success. Once you have registered for the event you will get an email with more details about how to join the live stream.

More about Annette Lennerup and why she is hosting this event:

Annette Lennerup, The founder of Fashion Design Tribe, supporting fashion brands and entrepreneurs with her 18 years of industry experience. Photo courtesy: Annette Lennerup

Annette said, “For the past 18 years I’ve worked in the fashion industry and the last 8 years I’ve been working with helping start-up and small fashion brands to learn about the industry and take their design to production. This is my passion and as I want to help a lot more brands and entrepreneurs I decided to host this event to share my knowledge.” “I have learnt about each step needed and know exactly what they need, both by helping others and also by having my own fashion brand for 6 years,” she added. From her vast experience, Annette learned how to create the best tech packs, how to find and communicate with manufacturers and how to sell the products, and she has also helped others do the same. Annette’s goal is to teach you to make the process of having a fashion brand much easier than going at it alone. You will love the community and have lots of fun with like-minded fashionpreneurs. You will also learn a lot about the fashion industry and filling in your gaps and helping you launch your product! All you have to do to join in, is to sign up for free! Just go to this link https://www.subscribepage.com/fashioncafe Don’t forget to join Annette’s Facebook group to meet like-minded fashionpreneurs. www.facebook.com/groups/fashiondesigntribe If you have something worth sharing to the world and get featured in Fashionnovation, e-mail us at fashionnovationfd@gmail.com

To know about Free and Paid Fashion Illustration courses, you can go here!

by Purba | Nov 23, 2021 | Fashion Illustration, Our works |

Fashion illustration is a great tool for fashion designers to express their ideas to their potential customers. As a picture can speak a thousand words, fashion illustration lets a designer to communicate easily. Fashion illustration is taught in every fashion institutions and Department of Textile Fashion and Design of Bangladesh University of Textiles is not an exception. Here are some of the stunning fashion illustrations from different batches of the students and members of Fashionnovation.

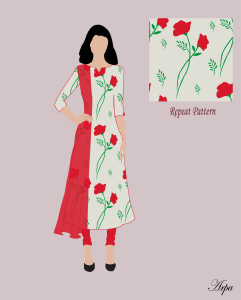

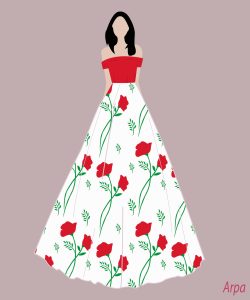

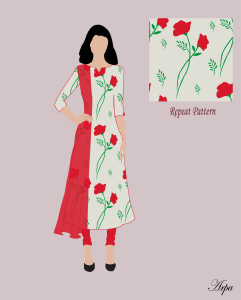

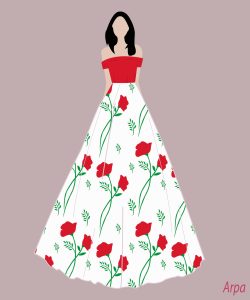

1. Fashion Illustration with print repeat designs by Sumaiya Ferdousi Arpa

Sumaiya Ferdousi Arpa’s striking illustrations with seamless print repeat designs are striking. The floral designs with vibrant colors are an expression of femininity.

Fashion illustration by Sumaiya Ferdousi Arpa. Fashionnovation

Fashion illustration by Sumaiya Ferdousi Arpa. Fashionnovation

Fashion illustration by Sumaiya Ferdousi Arpa. Fashionnovation

Fashion illustration by Sumaiya Ferdousi Arpa. Fashionnovation

Fashion illustration by Sumaiya Ferdousi Arpa. Fashionnovation

Fashion illustration by Sumaiya Ferdousi Arpa. Fashionnovation

2. Fashion illustration of Bangladeshi couple by Gulshan Ara Tasnim

Gulshan Ara Tasnim has done some amazing tasks with the dress design of Bangladeshi couple where she has designed saree and punjabi. The vibrant color and the details are noteworthy. She has also produced an anime type character which represents her Otaku feelings.

Fashion illustration by Gulshan Ara Tasnim. Fashionnovation

Fashion illustration by Gulshan Ara Tasnim. Fashionnovation

Fashion illustration by Gulshan Ara Tasnim. Fashionnovation

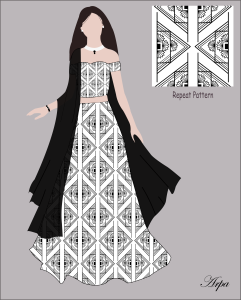

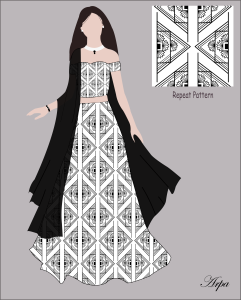

3. Western Dresses by Jinnat Ara Ferdous

Jinnat ara ferdous has experimented with western dresses and her striking detail works are visible which shows her expertise of focusing on the details. She has done some intricate patterns on her dresses and worked with darker colors. All in all her details her praiseworthy and as a student these works are certainly a sign of excellence!

Illustration by Jinnat Ara Ferdous. Fashionnovation

Illustration by Jinnat Ara Ferdous. Fashionnovation

Illustration by Jinnat Ara Ferdous. Fashionnovation

That’s all for today! Fashionnovation will showcase more of such amazing works in the future. Till then stay tuned and don’t forget to send your works like these to our email address: fashionnovationfd@gmail.com

Take care!

As you have read and seen these amazing works of fashion illustration, you might be interested to learn how they are done! Don’t worry! We got you covered here!

You can also read this premium article on the 21st century fashion!

And if you want to read one of our premium case studies on Fast Fashion Vs Slow Fashion, you can go here!

Fast Fashion Vs Slow Fashion: A Case Study

You can also see some more wonderful works of students below:

12 Basic Fashion Studies Sketches Done by Students That Will Inspire You In Your Next Fashion Study Lab Work

To be more creative like these fashion illustrators or to know the relationship between creativity and fashion, you can read this article named Creativity and Fashion Design!

To see how creative our members are, you should read another of our article where they have drawn some basic fashion sketches which will blow your mind!

Our Fashionnovation members don’t only draw sketches, they also create many creative and complex draping. To check that out, you can check our Fashion draping, variation of cascade article!

If you want to partner with us, collaborate, write articles or simply want to contact, feel free to email us at: fashionnovationfd@gmail.com

We always check your emails!

by Purba | Nov 23, 2021 | Shout out |

AMDA (Apparel Merchandising & Design Association) of Auburn University, Alabama and how they are working with the fashion students to shape the fashion world

What is AMDA?

AMDA is a platform available for the students in the merchandising and design majors within the Consumer and Design Sciences Department in the College of Human Sciences. The full form of AMDA is Apparel Merchandising & Design Association. It’s handled by Auburn University. AMDA represents the AMDP (Apparel Merchandising, Design & Production) program on campus and locally through private and public meetings and events. There are group meetings for members throughout the school year along with special events planned by the executive board. AMDA hopes to promote the AMDP students and facility by collaborating with other similar organizations and businesses to put on fashion shows, clothing drives and scholarships. AMDA was created to support and encourage AMDP students in their education and future careers within the apparel industry.

Auburn University’s Apparel Merchandising & Design Association. Source: AMDA Instagram page

AMDA’s Activity:

1. Fashion Event:

Fashion Event by CADS and AMDA. Source: AMDA

In 2011, the newly-formed AMDA, the professional organization for Auburn apparel students, relied on local connections to arrange the premiere Fashion Event. Accessories were borrowed from a vintage shop, a salon in town provided hair and makeup and even venue space was donated to the effort. Everything down to the music – played then on an iPod – was planned with just a $300 budget and students’ drive to succeed.

But at last, with attendance nearing a thousand, the Fashion Event has become widely known as Auburn’s premier creative showcase of student work, connecting apparel students with the industry’s best internships and job placements

Fashion Event by CADS and AMDA. Source: AMDA

And now whoever wants to see unconventional feats of fashion and fresh apparel design are invited to experience The Fashion Event – Auburn University’s premier fashion showcase featuring creations by the next generation of fashion designers and merchandisers. Actually this fashion event is a fashion showcase featuring creations by the next generation of fashion designers and merchandisers.

Year after year, students have said The Fashion Event is an invaluable experience for aspiring apparel designers and merchandisers, offering them the opportunity to learn the ins and outs of a design show before they even graduate. ty. The purpose of the event is to showcase the work of AMDP students demonstrating their creativity, versatility, and capability as future fashion professionals in multiple career paths.

Fashionnovation Your Mentor Talks’ First Episode with Ms. Ummey Hani Barsha

2. AMDP:

The AMDP program offers two undergraduate options — Apparel Merchandising (APME) and Apparel Design and Production Management (APDP) – as well as Master’s and PhD level opportunities. Auburn’s nationally ranked apparel programs do a great job of preparing the graduates for careers in today’s global apparel industry. An integrated approach to studying apparel throughout the supply chain provides students with the education and experiences to become a valued member of firms throughout the apparel and related industries.

3. “SWATCH” Magazine:

In the fall 2020 semester, officers in the AMDA, created a magazine named “SWATCH”, a student-driven publication. This magazine features original content and innovative designs from Auburn’s apparel students in the College of Human Sciences.

SWATCH magazine by Auburn University’s Apparel Merchandising & Design Association. Source: AMDA

SWATCH magazine boosted morale, encouraged creativity and provided valuable experience for Auburn students amid the COVID-19 pandemic. This magazine has published many blogs within this recent times.

4. Sustainable Course:

AMDA provides a sustainable course which is actually about fashion & sustainability through which student can understand luxury fashion in a changing world & can be aware about maintaining sustainability.

Auburn University’s Apparel Merchandising & Design Association

Future Goals:

1.AMDA wants to build up student network with professionals in the industry which will help them to enrich their practical knowledge. And thus they can create relationships & obviously will be benefitted to lead internships & jobs.

2. They are focused on advancement throughout the graduates’ career. Lifelong learning and transferable skill sets are emphasized.

3. AMDA wants to make “A Healthier U” & already students of AMDA are committed to using repurposed fabric for handmade, fashionable masks. Their target is to sell every mask for $5 and to place the orders by the end of the day.

https://www.linkedin.com/company/apparel-merchandising-and-design-association#:~:text=AMDA%20is%20an%20organization%20available%20for%20the%20students,locally%20through%20private%20and%20public%20meetings%20and%20events.

http://ocm.auburn.edu/newsroom/campus_notices/2021/01/071106-auapparel.php

https://www.swatchbyamda.com/

https://www.instagram.com/p/CO59zdhtkCd/

http://ocm.auburn.edu/newsroom/campus_notices/2020/07/241351-mask-fundraiser.php

-Team Members:

1. Tamanna TAbassum

2. Gulshan Ara Tasnim

3. Nazmin Akter Shaila

4. Nashita Ahmed

You might also be interested to read about National Institute of Fashion Technology (NIFT), Hyderabad, A Heaven for The Fashion Learners

You might also be interested to read about Fashionnovation Your Mentor Talks’ First Episode with Ms. Ummey Hani Barsha!

As you’re interested in fashion design learning and activities, you might also be curious about how much a fashion designer makes hourly, daily, monthly and yearly. To know that read this article.

by Purba | Oct 28, 2021 | Fashionnovation events |

On September 26, 2021, Fashionnovation arranged a session with Ms. Umme Hani Barsha, an ex-student of BUTEX batch-38 and also Adjunct faculty of Department of Textile Fashion & Design (TFD) of Bangladesh University of Textiles (BUTEX) who is currently studying MS in Consumer & Design Science, majoring in Design and Applied Arts at Auburn University. She is our first guest in “Fashionnovation Your Mentor Talks.” She is one of the dearest mentor and well-wisher of Fashionnovation and she supported the platform from the beginning of its journey, right from 7 July 2018.

In that session, our discussion areas were higher studies in fashion, building up and honing skills related to fashion and how to enjoy life to the fullest-valuing each and every experience we gather. In the session, BUTEX 43, 44, 45 & 46th batch joined spontaneously and all credits of managing & directing the session goes to the Founder & President Kazi Farhan Hossain Purba.

Our guest- Ms. Barsha started the session by stating the most valuable advices of her Professor which are- Always ask questions! Because in graduation life, whoever is curious to know more, he/she will be more successful in his/her life.

Fashion design higher study guidelines:

Ms. Barsha then guided us about higher studies. If a student wants to pursue his higher education in Europe, then the student must have an excellent portfolio. European Universities demand more practical knowledge in the design sector that can be shown through portfolios. Students who are interested in studying in the U.S.A, mostly need to take GRE. In many institutions, they demand good verbal scores on GRE. A few institutions waived GRE recently also. In the USA, very few universities offer textile engineering degrees directly. One of them is North Carolina State University. Students may look at other departments like dept. of Material Science (students from the dept of Fabric & Yarn engineering), dept. of Chemical engineering (students from the dept of Wet Process Engineers & Dyes and Chemical engineering), dept. of Industrial engineering. Most of the institutions offer graduate degrees in Apparel Merchandising and Apparel Designing or Fashion Designing under the department of Consumer and Design Sciences or Agriculture.

Then if you want to go to Germany, fashion design students may face some challenges. Usually, there are no tuition fees for most of the courses but in fashion design as well as other art-based subjects such as architecture, and photography, students are required to pay tuition fees. Few colleges have no tuition fees but they teach in the German language instead of English. This is the scenario for many other European universities like Italy, France, and the Netherlands. If they know their language, then they can apply for Dutch and French scholarships respectively. Italy, Netherlands, New Zealand, and Denmark also have textile-related universities as well as they offer graduate degrees in fashion. ArtEZ from the Netherlands offers a master’s in fashion in English, and they have scholarships. In New Zealand, you can get a government scholarship in the design sector from Auckland University. For applying in Denmark, one must complete the first level of their language. In Japan, there is a great fashion design school named Bunka Fashion College which ranks in the top 20 in the world. In Hong Kong Polytechnic, there are mainly PAD courses but you can also go through your graduate level here.

Then if you want to go with Australia or Canada, it will be suitable if you can go on a fully funded scholarship. Pertinently, it must be included that there is only one university in Canada named Ryerson that offers a graduate degree in fashion design. The University of Toronto, the University of Manitoba, and the University of Alberta offer textile-related subjects like material science and other degrees. In Australia, RMIT offers a graduate degree in fashion design as well as textile engineering. There is a scholarship for women but that requires two years of working experience.

You will be happy to know that there was a special guest in our session whose name is Mr. Asef Amer Priyo who is also our BUTEXian senior from the same batch of Ms. Barsha. And he is now working in Decathlon Sports Bangadesh, having working experience of 4.5 years in the industry. He advised to enrich English communication skill, presentation skill and learn Microsoft Excel & Powerpoint from undergraduate level. He clarified about the job sectors of Textile Fashion Design as well as Textile Engineering. He said actually one will get a job or not it totally depends on the performance at the interview board and how much your CV is enriched. Also you must have a very strong portfolio. And at the interview board, you must know what you say and know what you know.

Then again Ms. Barsha said a fashion designer must have knowledge about the fabric, its drapability, texture, etc besides art and design. Because fabric, stitches, pattern-these all are strongly connected with fashion.

When one of the participants of that session asked about the importance of CGPA in higher studies, Ms. Barsha replied that a high CGPA is not a must for applying for foreign scholarships. But if you want a fully funded scholarship and a good subject as per your choice then you will be much benefited if you have a high CGPA. But don’t be upset if it’s by chance low because you can cover it up with other facts like having a great portfolio as well as achieving high scores in speaking & writing on IELTS and GRE scores.

Mr. Asef Amer Priyo was sharing his vauable experience with the audience.

Is having a published research paper important for higher studies?

Another question came from the participants about the importance of research papers. Madam replied that actually on the master’s level, teachers of foreign universities do not really expect research papers from the students. Students may have a review paper which is helpful also. But one should have a clear knowledge of their research interests. She again mentioned having a strong portfolio always helps. She referred to a YouTube channel named Zoe Hong to enrich your portfolio. She also suggested a site named issuu.com see many kinds of portfolios there.

Ms. Barsha said that during her application for MS, she categorized the ranking of the university where she applied and research interests and if the university provides funds or not. Again another student asked her about what can the student do with fashion degrees. Madam replied there are fashion photography, visual merchandising, fashion merchandising, sourcing sector & designing sectors. Last, of all, she stressed upon especially for fashion design students to learn Adobe software like Adobe Photoshop, Adobe Illustrator, etc.

At last our special guest Mr. Asef gave us some life hacks. He said,”Forget about being disheartened. No knowledge is small, no knowledge is short! So if you have leisure, it’s better to learn something new. Always use your time efficiently.” Then Barsha madam suggested, “Obviously do work but enjoy your life to the fullest in your undergrad!”

It was really an amazing session! We learnt a lot from Ms. Barsha & Mr. Asef. We are expressing our gratitude to them and the organizer of this session, Mr. Kazi Farhan Hossain Purba. Hope that we will get more sessions like this & will be able to learn a lot!

Nashita Ahmed

Dept.Environmental Science & Engineering,

Bangladesh University of Textiles (BUTEX)

ID: 2020-1-10-041

You can also read our article about Auburn University’s AMDA, their activities and goals!

Auburn University’s AMDA, Their Activities & Goals

You might also be interested to read about National Institute of Fashion Technology (NIFT), Hyderabad, A Heaven for The Fashion Learners